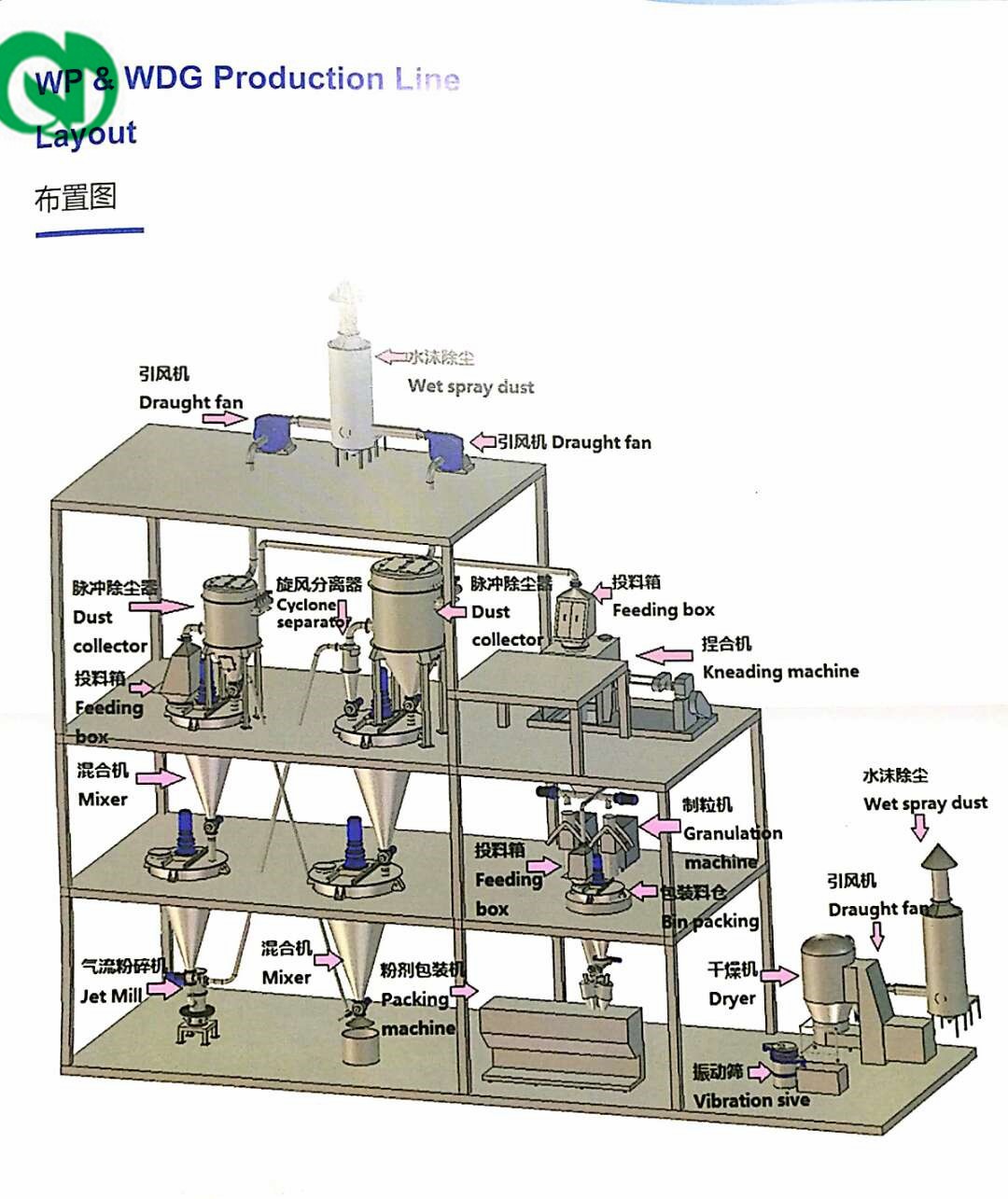

Inkqubo yeWP-WDG–Faka kwiNdawo yeAgrochemical

WP inxalenye

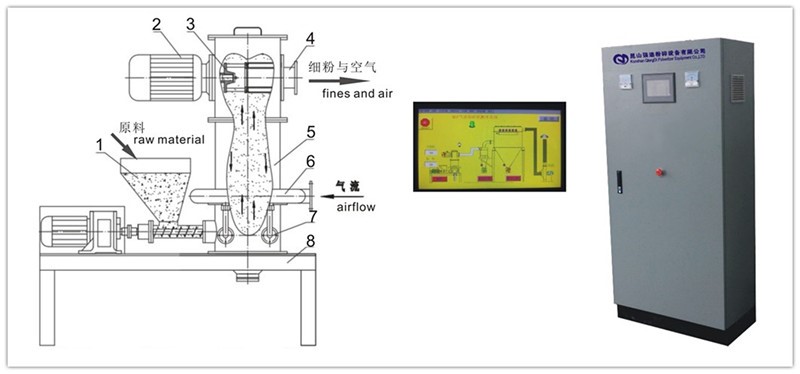

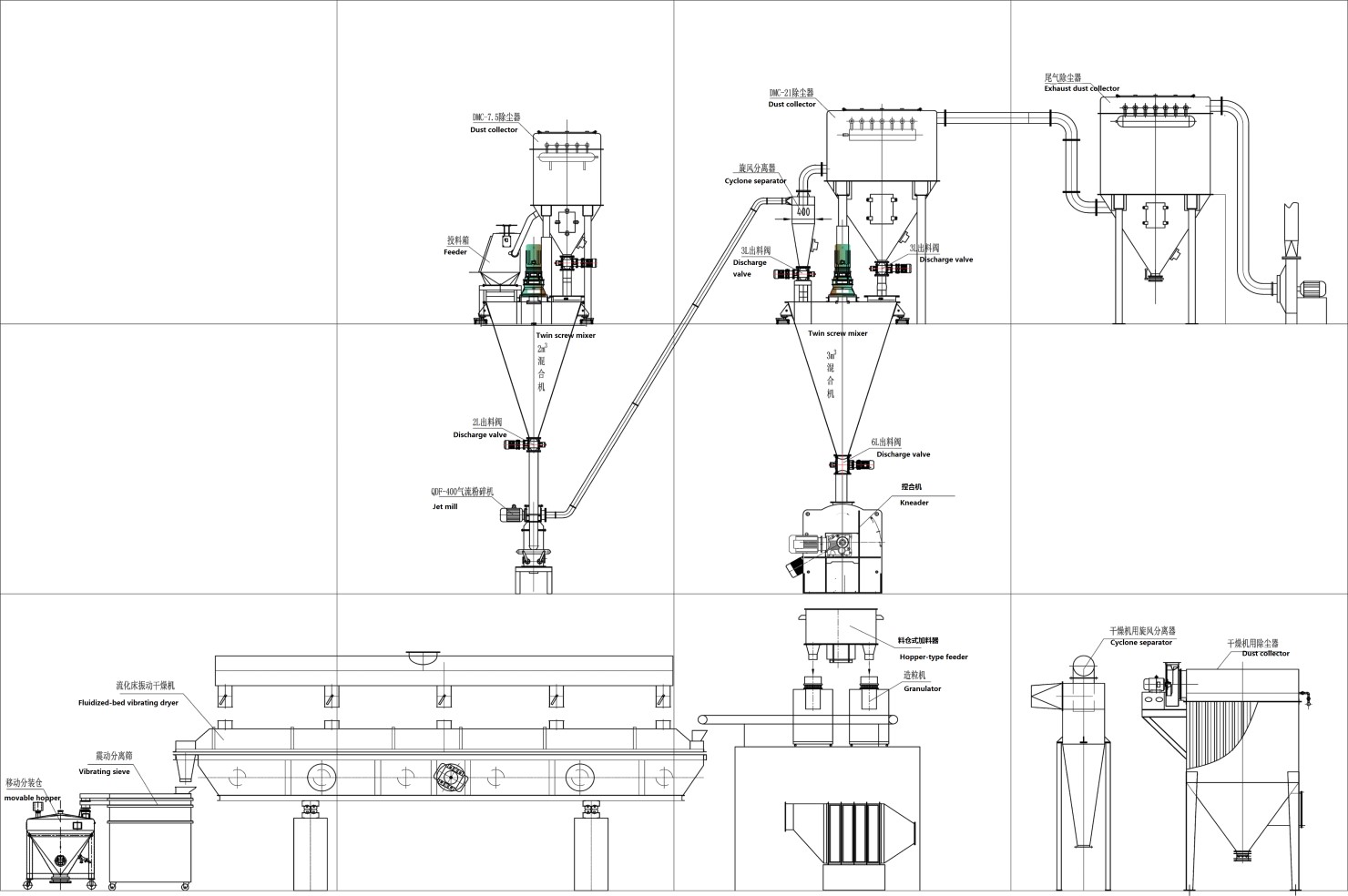

Okokuqala, Isondlo semathiriyeli ekrwada ukusuka kwi-feeder --ukudluliselwa kwemathiriyeli ukuya kwi-3 m yokuqala3umxube we-premixing, kunye nomqokeleli wothuli uya kuqokelela uthuli ngexesha lenkqubo yokutya, emva koko izinto ezixubeneyo zingene kwi-jet ye-QDF-600 ye-jet yokusila, ubungakanani be-particle ye-output ingakwazi ukulungiswa ngokulungelelanisa isantya esijikelezayo esahlukileyo sevili lomlinganisi,. Emva kokugaya, izinto ziya kudluliselwa kwi-cyclone kunye nomqokeleli wothuli phezulu kwe-4m yokuqala3i-mixer ngokusebenzisa amandla e-centripetal ye-draft fan, emva koko udlulisele kwi-4m yesibini3umxube wokuxuba phambi kwephakheji okanye ukudluliselwa kwinkqubo ye-WDG.

Inkqubo yeWP yindibaniselwano egqibeleleyo yeteknoloji ye-jet mill, iteknoloji yokuxuba kunye neteknoloji yokulawula ingqiqo. eyimveliso eyanelisayo yezibulali-zinambuzane ukuxutywa kaninzi kunye ne-remix,Ngeli xesha, idibana nesicelo sokusingqongileyo ukuba kungabikho luthuli ngexesha lenkqubo yonke.

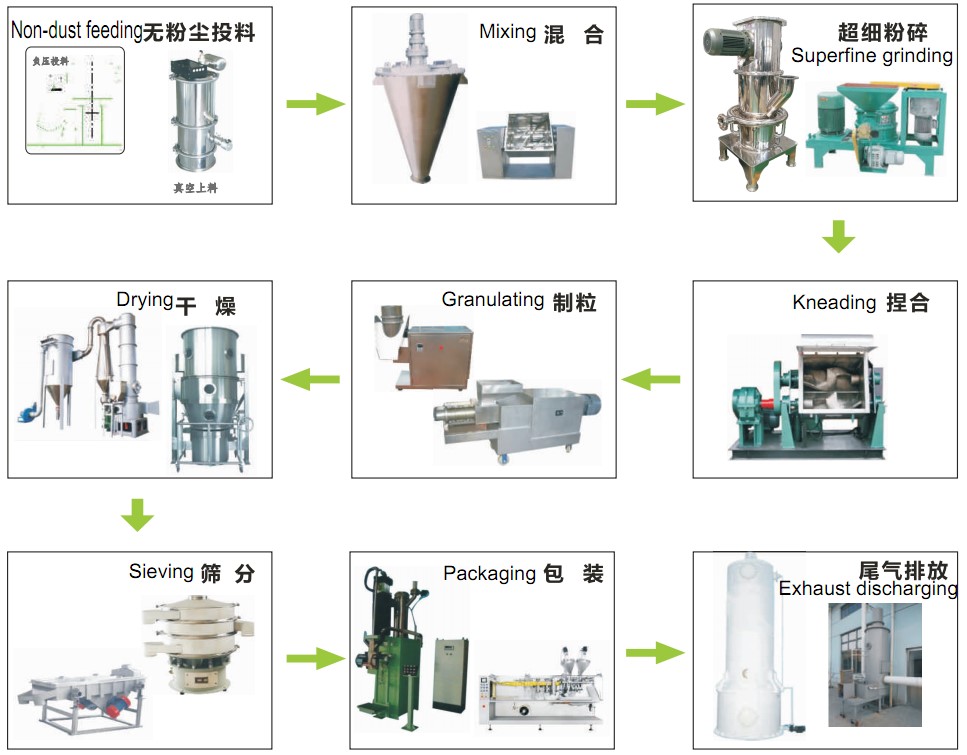

I-WDG (i-granule ehlakazekayo yamanzi) eyaziwa ngokuba yi-ejenti emanzi eyomileyo yokumisa i-agent okanye uhlobo lwenkozo, izinto eziluhlaza zomgubo omanzi (WP) ezenziwe nge-granulation kanye emanzini, zinokutshatyalaliswa ngokukhawuleza kwaye zihlakazeke, i-granular yokulungiselela ifom ye-dispersion ephezulu emisiweyo.

Igranulation ngundoqo wenkqubo yonke. Igranulator isitshixo sokuqinisekisa ukuba amayeza okubulala izitshabalalisi egranulated kunye nenkqubo yokomisa icon-figured, esekelwe kwiimpawu zezitshabalalisi, idatha yovavanyo kunye nemizekelo yesicelo sobunjineli, ukukhetha igranulator ejikelezayo ye-extrusion okanye i-twin screw extruder granulator. inkqubo kunye nenkqubo ye-granulation ye-extrusion iyahluka) .Imfuno yomswakama we-granulation malunga ne-8-18%.Ngokusekelwe kwiimpawu zemveliso kunye neenkqubo zokuvelisa, ukumisela ukuyilwa kwenkqubo ikakhulu kuqulethwe: ukuxova, ukuxubha, ukomisa, ukukhangela, ukupakishwa, iinkqubo zomoya oshushu, inkqubo yokususa uthuli.

Okokuqala, imathiriyeli ekrwada iya kuthuthelwa kwi-1000L Buffer, emva koko itto ZGH-1000 umatshini wokuxuba othe nkqo ngeVacuum ZKS-6 yokuxuba okumanzi emva koko uthuthelwe kwi-XL-450 extrude granulator (3pcs) nge-500L yokusasaza kwigranule emanzi, emva koko ukuya kwi-QZL-G070 ukuya kwi-ZQ-130. Vibrate Fluid-bed Dryer strip granules then ZS-1800 centrifugal vibration sieve for sieve ukufumana iigranule zobungakanani obufunekayo.

Isisomisi sebhedi esingcangcazelayo somgubo wekhemikhali

Isisomisi sebhedi esingcangcazelayo somgubo wekhemikhali

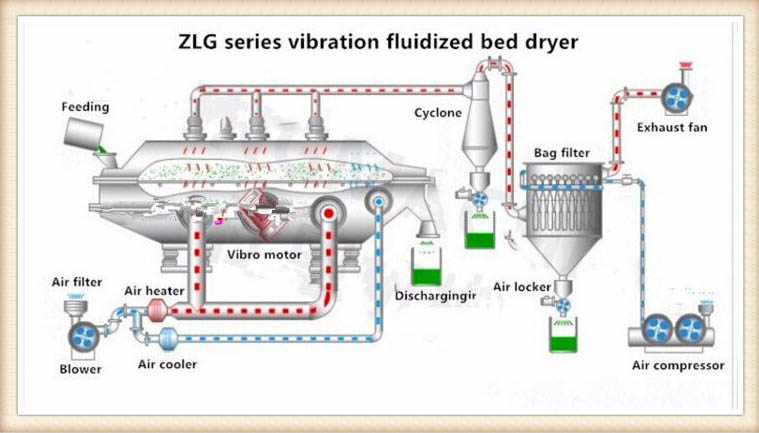

UmGaqo wokuSebenza

Ibhedi yolwelo lokungcangcazela bubuchwephesha obutsha obuphuhliswe ngokwesiseko sebhedi emileyo. Ukungcangcazela komatshini kongezwa kwibhedi emanzi. Amasuntswana ezinto ezimanzi angena kumlambo womoya aze enze ibhedi yolwelo. Izinto eziphathekayo zikhutshiwe ngenxa yamandla anika umdla. Ukushukuma kwepleyiti yokusabalalisa umoya kukukhuthaza ukuchithwa kwezinto eziphathekayo kunye nokuhamba kwezinto kwibhedi yamanzi. Izinto ezilulwelo zinxibelelana nomoya oshushu kwaye kwangaxeshanye ziqhubela phambili ubushushu kunye nokuhanjiswa kobuninzi. Imveliso eyomileyo ikhutshwe nge-port yokukhupha.

Iimpawu

1. Isebenzisa iteknoloji ye-vibrofluidization ephezulu, umonakalo we-particle eyomileyo ye-particle surface incinci.

2. Ukunyakaza okuzinzile, ukulungelelaniswa kakuhle.

3. I-Vibrations ibangela i-fluidization, isantya sokuhamba komoya esomileyo siyancitshiswa, kwaye iinqununu ezimbalwa zifakwe.

4. Ixesha lokuhlala kwezinto eziphathekayo lihambelana, umgangatho wemveliso ufana.

5. Isetyenziselwa ukomisa izinto ezinobushushu ngexesha elifutshane, njengamanzi angaphezulu

ukomiswa kweCUSO4 · 5H2O equlethwe ngamanzi e-crystal, MgSO4 · 7H2O.

Umda osebenzayo

Ingasetyenziswa kwinkqubo eyomileyo okanye yokupholisa, esebenzayo kwi-particle bulky okanye amaqhekeza kwaye akukho lula ukuhamba kweemveliso ezingaqhelekanga, okanye ngenxa yokuba ukwenza amaqhekeza angabizi kakhulu kwaye agcine isantya esipheleleyo se-fluidization yeemveliso kunye nokulula ukubopha, uvakalelo lokumisa ubushushu kwaye ziqulathe izinto ze-gesso imveliso kumphezulu wokususwa kwamanzi ukusuka.

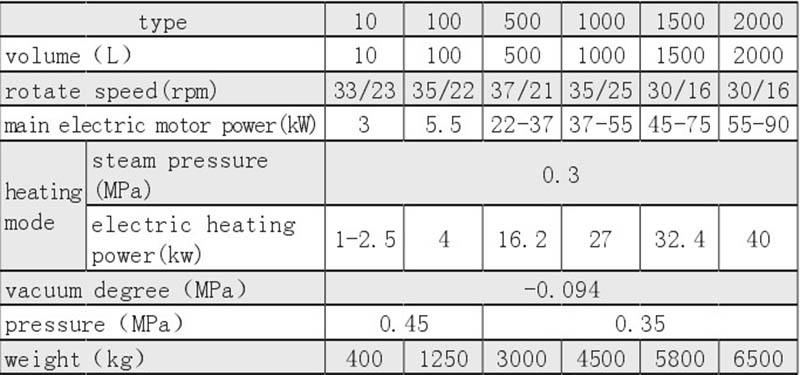

Ipharamitha yobugcisa

| Umzekelo | Indawo yebhedi enolwelo (M2) | Ubushushu bomoya wokungena (oC) | Ubushushu bomoya wokuphuma (oC) | Umthamo wamanzi aphuphumayo (ikg) | Imoto | |

| Umzekelo | Kw | |||||

| ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

Izicelo ngokubanzi

Lo matshini uthatha iperi enye ejikelezayo yokugaya i-blade ukugaya izinto ezimanzi kwi-colum-shape granule nge-cylinder ye-sieve yensimbi engenasici ebonelelwa nge-pelletize kwinkqubo elandelayo.

Iyakwazi ukucubungula izinto ezimanzi kwaye ifumane ubukhulu obuhlukeneyo ngokwezinto eziphathekayo kunye neemfuno.

UMGAQO WOKUSEBENZA:

Amandla emoto ahanjiswa ngesondo lebhanti elingunxantathu kwibhokisi yegiya kwinginginya, kwaye isasazwe amandla ngamacandelo okuhambisa kwibhokisi yegiya. Yongeza imathiriyeli eluhlaza kwi-hopper yokutya, yicinezele ukusuka phezulu.

Emva kokuxuba, izinto eziphathekayo zixutywe kwi-chute yokutya kunye nokunyanzeliswa kwangaphandle kwe-extrusion nge-blade ekhethekileyo. Xa i-material ixinaniswe kwi-gap phakathi kwe-blade kunye ne-screen mesh, imela yokusika iya kuyinqunqa ibe yisayizi yokudibanisa.

Iiparamitha zobuGcisa:

| Ukuphuma | I-150-250kg / iyure (i-flake shape), 50-100kg / iyure (igranule shape) |

| Ubungakanani begranule | 0.5-2mm |

| Uxinzelelo olukhulu | 294Kn(30T) |

| Uxinzelelo lokutywinwa kwecala | 9.8Kn |

| Ukutya injini | 2.2Kw |

| I-Granulating Motor | 2.2Kw |

| Ukucinezela injini | 7.5Kw |

| Ukutya isantya screw | 6-33 ehlengahlengiswayo |

| Ukucinezela isantya sevili | 4-25 ehlengahlengiswayo |

| Ubungakanani bevili lokucinezela | 240X100mm |

| Ubunzima (malunga) | 2000Kg |

| Ubungakanani beyunithi ephambili | 1600X1000X2300mm |

| Ubungakanani bekhabhathi yokulawula | 600X400X1300mm |

Ukusetyenziswa

Umatshini ubukhulu becala ulungele ishishini lamachiza, imboni yokutya, imboni yesiselo esiqinileyo njalo njalo, Inokwenza izinto ezikrwada zivuselelwe qranuate qanule efunekayo. Ngokukodwa, ifanelekile kwizinto eziluhlaza ezine-adhesive encangathi.

Iimbonakalo:

Zonke iinxalenye ezidityaniswe nezinto ezikrwada kulo matshini zenziwe ngentsimbi engenasici. Inkangeleko yayo bubuhle. Ukukhutshwa kwayo ngokuzenzekelayo.Ngoko ke kunokuphepha iimeko ezonakalisiweyo ezibangelwa yincwadana. Ifanelekile kwimveliso yomgca kwakhona.

Iipatameters eziphambili zobugcisa

| Ubungakanani bemela yokusila(mm) | 300 | 400 |

| Ububanzi begranule(mm) | Φ2~2.2(Isenokuba ngokungqinelana neemfuno zabathengi) | Φ1.2~3(Isenokuba ngokungqinelana neemfuno zabathengi) |

| Imilinganiselo iyonke(mm) | 700×540×1300 | 880×640×1300 |

| Amandla emoto(kw) | 3 | 4 |

| Ubunzima(kg) | 350 | 400 |

| Umthamo wemveliso(kg/h) | 100-200 | 140-400 |

Umgaqo

Isixhumi sodidi oluthe nkqo lwe-LGH lwenziwe ngamaphini okubhexa asezantsi kunye neephini ezityumzayo ezinesantya esiphezulu, amaphini asezantsi aqhubelekayo athumela imathiriyeli phezulu ecaleni kodonga lwesikhongozeli.

Isantya esiphezulu sokutyumza ii-oars zaphula izinto ngokupheleleyo ukwenza umjikelo wezinto ezifana ne-vortex, ukugqiba ukuxubana ngokulinganayo ngexesha elifutshane.

Iimpawu zezixhobo

Umatshini wokuxuba we-LGH othe nkqo wesantya esiphezulu lolona hlobo lutsha loxuba olusebenzayo kumzi-mveliso wethu, oluqokelele ubuchule obuphambili basekhaya naphesheya kolwandle.Ezona mpawu ziphambili zezi zilandelayo:

1.Amaphini ezinto ezisezantsi ahlala ethumela imathiriyeli phezulu nge-centrifugal force. Kwaye izinto eziphezulu ziwela ezantsi embindini, ukwenza umjikelo wezinto ezibonakalayo njenge-vortex.

2.Isantya esiphezulu amaphini okubheqa aqhekeza imathiriyeli yobuninzi ngokupheleleyo ethunyelwa ngamaphini asezantsi.

3.Izinto eziphathekayo zinokuxutywa ngokufanayo ngexesha elifutshane ngenxa yokubheqa okumbini kwe-high-speed revolution. Isantya sokuxuba kunye nokufana kweyona nto ibhetele kuzo zonke iintlobo zomatshini wokuxuba kwiimarike zasekhaya. Ukufana ngumxube we-100%.

4.Qalisa i-valve yokukhupha, isantya sokukhupha ngokukhawuleza, kwaye umatshini kulula ukuwucoca.

I-5.Izixhobo zoqhagamshelwano zomatshini zenziwe ngensimbi engenasici, ngexesha lenkqubo yokuxuba, izinto eziphathekayo aziyi kuguquguquka, i-metamorphic kwaye ilahleke.

6.Umatshini ulungelelanisa izinto ezahlukeneyo ezomileyo nezimanzi ukuxuba, ngokukodwa iisuti zokuxuba i-essence yenkukhu, iyeza elinyibilikisiweyo, isiselo esinyibilikisiweyo kunye nokunye.

Ikwabizwa ngokuba yi-rotary vibro sifter,vibratory sieve.Inokucoca ulwelo njengamanzi amdaka kunye neoyile yenkunkuma njl,njl, susa ukungcola kwizinto eziphathekayo, ezinjengomgubo wobisi, irayisi, umbona njl.

Iinkcazelo

Umatshini we-rotary charcoal/coal ultrasonic vibrating screen sifter wamkelwe iindlela eziphambili zokujonga izixhobo ezikumgangatho ophezulu. Iqukethe umvelisi we-ultrasonic kunye nesikrini sokungcangcazela. Yimpumelelo ebalulekileyo ekuhloleni ukusebenza kakuhle. Lo matshini we-sieving wamkela isilawuli se-ultrasonic esilumkileyo esinengqondo kwaye uzisombulule iingxaki ezininzi ezibangelwa yi-frequency enye, ngokwenene ukuqonda ukudibanisa okufanelekileyo komsebenzi we-ultrasonic kunye ne-vibration sieve.

Imisebenzi emininzi ngolu hlobo lulandelayo:

1. Ukuhlelwa

Uhlobo lwe-multi-layer lunokukhusela kwaye lwahlule amaqela amahlanu amaqhekeza ahlukeneyo ngexesha elinye. Ifanelekile kwizinto ezomileyo.

2. Ukuhluzwa

Umxube wezinto eziqinileyo kunye nolwelo zinokwahlulwa ngokufanelekileyo ngohlobo olulodwa okanye lwe-multi-layer kwizinto zebakala ezahlukeneyo.

3. Susa ukungcola

Iyunithi inokukhawuleza ukwahlula amaqhekeza amancinci amancinci okanye ngaphantsi kobuninzi bezinto eziphathekayo

Inkqubo yokucoca sisebenzisa isixhobo se-ultrasonice kwi-Rotary charcoal/coal ultrasonic vibrating screen sifter machine

Iphathi ezisecaleni

I-Kneader sisixhobo esifanelekileyo sokuxova, ukuxuba imathiriyeli ye-polymerize ene-viscosity ephezulu kunye neplastiki ye-elasto. Iseti nganye ye-kneader inamaqhekeza amabini e-sigma blades ngaphakathi kwegumbi lokuxuba lodidi. Isetyenziselwa kakhulu ukuxova, ukuxuba, ukutyumza, ukusasaza kunye nokuphinda wenze i-polymerize intlama ye-viscosity ephezulu okanye izinto ze-elastoplastic, ezingenakulungiswa ngabaxube bepowder ngokubanzi kunye nezixube zolwelo. Ingasetyenziselwa kumashishini afunekayo ekuxinaniseni okuphezulu okufana ne-agrichemical, ikhemikhali, irabha, ukutya kunye nokulungiselela amayeza. Isiphumo singcono kunomxube. I-Kneader sisixhobo sokuxuba esikhethekileyo esinamaqabunga amabini. Okhawulezayo udla ngokujikeleza ngesantya esingama-42 ngomzuzu, ecotha enye ngesantya esingama-28 ngomzuzu. Izantya ezahlukeneyo zenza izinto zokuxuba zifumane i-homogenate ngokukhawuleza.

Ubunjineli beZityalo

- Uyilo lwesityalo

-Ukubeka iliso kwinkqubo, ulawulo kunye ne-automation

-Uphuhliso lweSoftware kunye nenkqubo yesicelo sexesha lokwenyani

- Ubunjineli

- Ukwenziwa koomatshini

Ulawulo lweprokjekthi

- Ucwangciso lweprojekthi

-Ulawulo nolawulo lwesiza sokwakha

- Ukufakwa kunye novavanyo lwezixhobo kunye neenkqubo zokulawula

- oomatshini kunye nokugunyaziswa kwezityalo

- Uqeqesho lwabasebenzi

- Inkxaso kuyo yonke imveliso

Inkcazo yeProjekthi

- Ukuba nokwenzeka kunye nofundo lwengqiqo

- Iindleko kunye nokubalwa kweNzuzo

-Ixesha kunye nesicwangciso sobutyebi

-Isisombululo se-Turnkey, ukuphuculwa kwezityalo kunye nezisombululo zesimanje

Uyilo lweProjekthi

- Iinjineli ezinolwazi

- Ukusebenzisa itekhnoloji yamva nje

- Ukusebenzisa ulwazi olufunyenwe kumakhulu ezicelo kuwo nawaphi na amashishini

-Ukwandisa ubuchule obuvela kwiinjineli zethu ezinamava kunye namaqabane