Ukusetyenziswa okuKhethekileyo kwe-Fluidized-bed Jet Mill kwizinto zobunzima obuphezulu

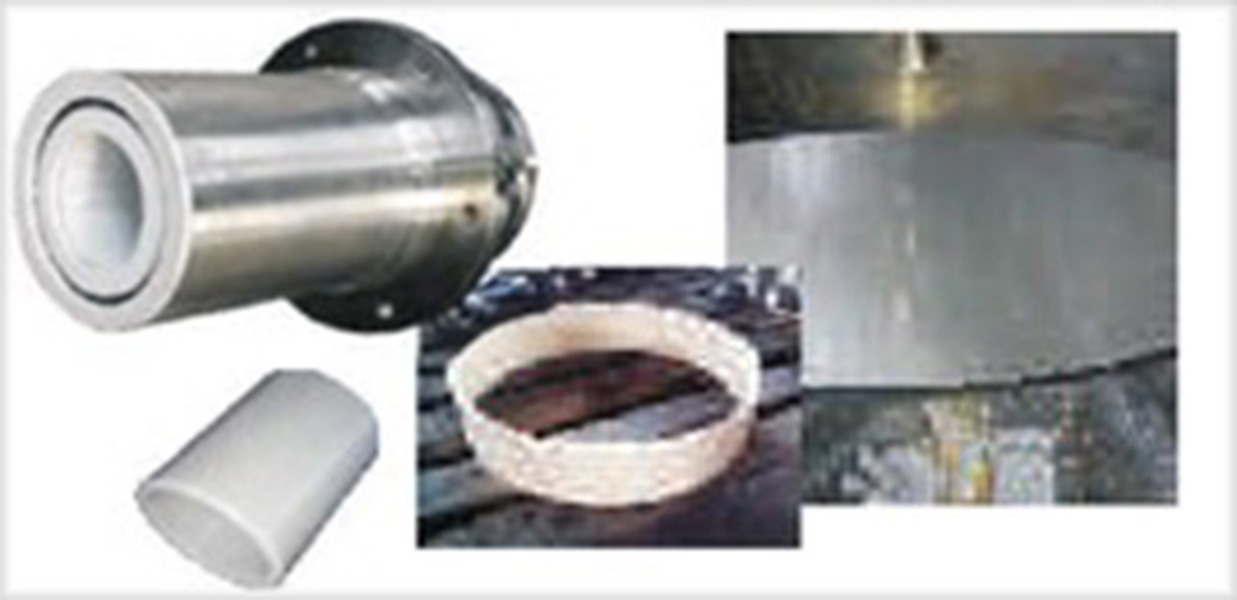

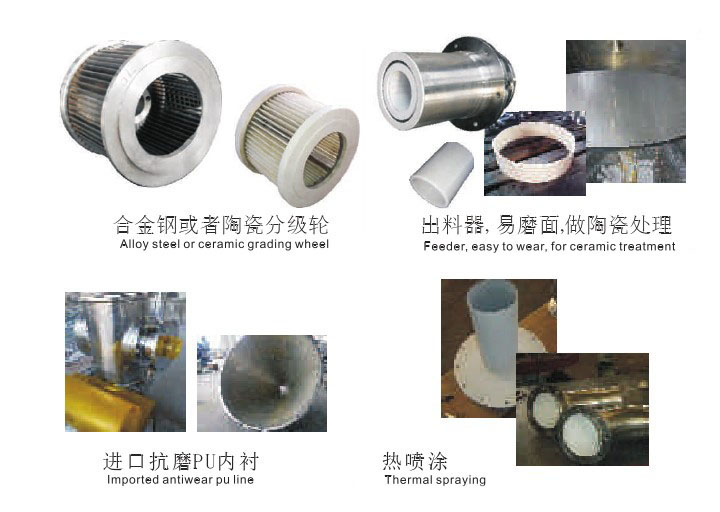

● Ukuncamathisela iPU okanye iiseramikhi kwisahluli senkanyamba kunye nomqokeleli wothuli.

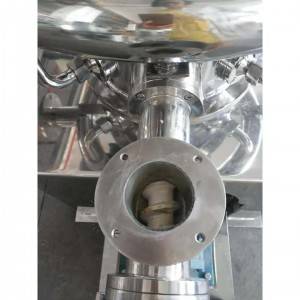

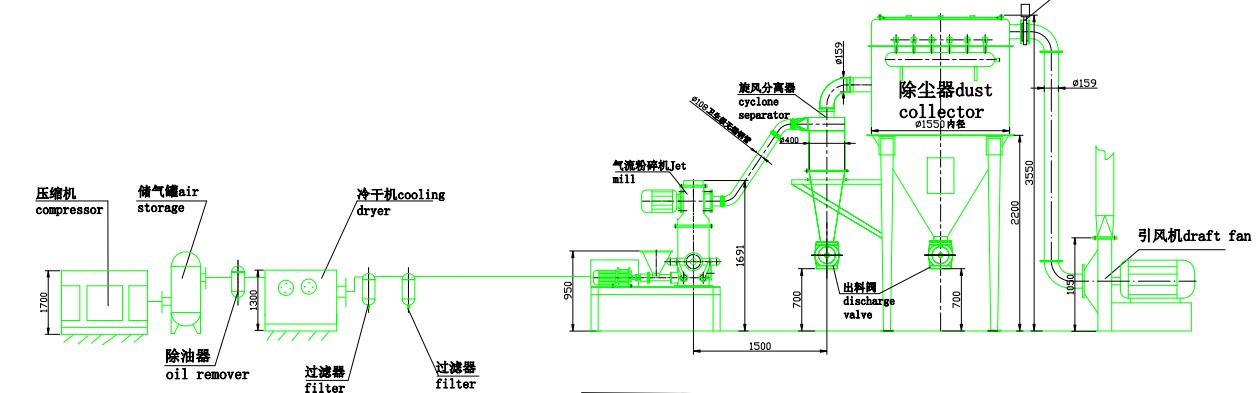

Inkqubo yokugaya i-jet mill iquka i-jet mill, i-cyclone, i-bag filter kunye ne-draft fan. Umoya ohluziweyo, oyekisiweyo kunye nocinezelekileyo ukhutshelwa kwigumbi lokusila ngokusebenzisa umbhobho womoya, imathiriyeli iyatyunyuzwa enye kwenye kwindawo edityanisiweyo yomoya wejethi yoxinzelelo oluphezulu kwaye ekugqibeleni ihlatywe. Emva koko, izinto eziphathekayo ziya kwahlulwa zibe ngamasayizi ahlukeneyo phantsi kwamandla e-centrifugal kunye ne-centripetal force. Amasuntswana amahle afanelekileyo aqokelelwa sisitshingitshane kunye nesihluzi sebhegi, ngelixa amasuntswana agqithisayo aya kubuyiselwa kwigumbi lokusila ukuze aphinde agaywe.

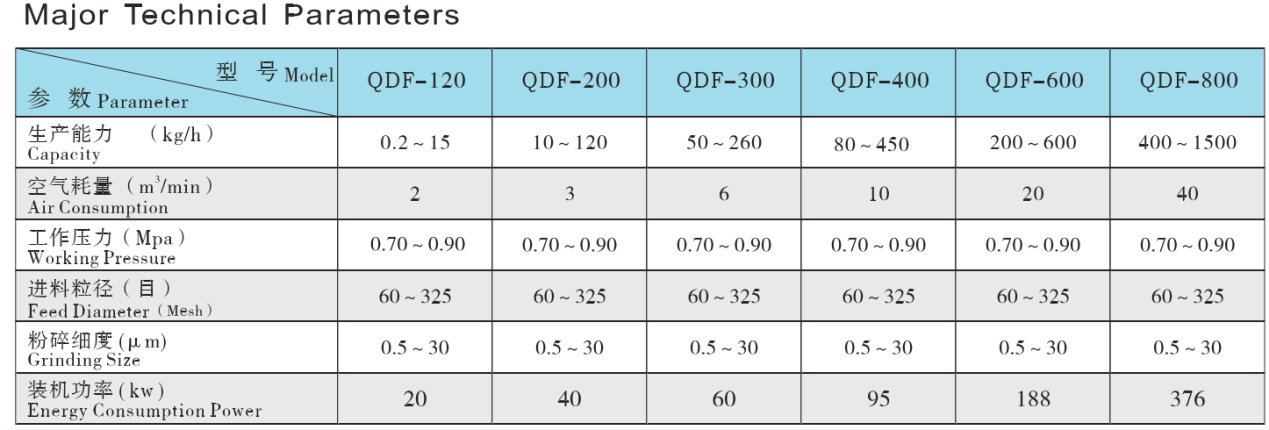

Amanqaku:Ukusetyenziswa komoya ocinezelweyo ukusuka kwi-2 m3 / min ukuya kwi-40 m3 / min. Umthamo wemveliso uxhomekeke kubalinganiswa abathile bezinto zakho, kwaye unokuvavanywa kwizikhululo zethu zovavanyo. Idatha yomthamo wemveliso kunye nokulunga kwemveliso kweli phepha zezereferensi yakho kuphela. Izinto ezahlukeneyo zineempawu ezahlukeneyo, kwaye ke imodeli enye ye-jet mill iya kunika imveliso eyahlukeneyo yokusebenza kwezinto ezahlukeneyo. Nceda uqhagamshelane nam malunga nesindululo sobuchule esilungiselelweyo okanye izilingo ngezinto zakho.

I-1.Iingubo ze-ceramic ezichanekileyo, i-flexible anti-wear lining evela kwinkqubo yokuhlelwa kwezinto eziphathekayo ukuqinisekisa ukucoceka kweemveliso. Ngokukodwa ezifanelekileyo kwiimveliso zobunzima obuphezulu, ezinjengeWC, iSiC, iSiN, iSiO2kwaye nangokunjalo.

2. Akukho ukunyuka kweqondo lokushisa: Iqondo lokushisa aliyi kunyuka njengoko izinto zixutywa phantsi kweemeko zokusebenza zokwandiswa kwe-pneumatic kunye neqondo lokushisa kwi-milling cavity ligcinwa liqhelekileyo.

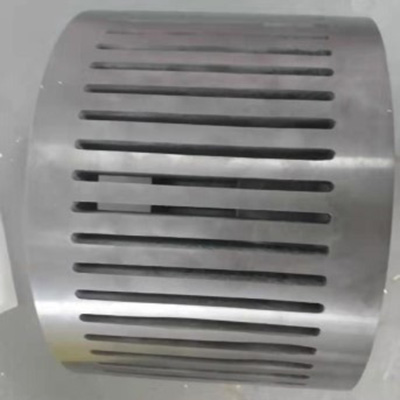

3.Ukunyamezela: I-Ceramic okanye i-SiO okanye i-Carborundum lining Ifakwe kwizinto ezinobunzima be-Mohs Grade 5~9. impembelelo yokusila ibandakanya kuphela impembelelo kunye nokungqubana phakathi kweenkozo kunokungqubana nodonga. ukuqinisekisa ukungadibanisi nesinyithi kulo lonke ukugaya ukucoceka okuphezulu kokugqibela.

4. Isantya sevili silawulwa ngumguquli, ubungakanani be-particle bunokulungiswa ngokukhululekileyo. Ivili lokwahlulahlula izinto ngokuzenzekelayo kunye nokuhamba komoya ukulawula ngokufanelekileyo ukucolwa kweemveliso ezigqityiweyo.Imveliso ye powder Ultrafine izinzile kwaye inokwethenjelwa.

Itshati yokuqukuqela kukusetyenzwa okusemgangathweni kokugaya, kwaye inokulungiswa kubathengi.

Inkqubo yokulawula ye-PLC

Inkqubo ithatha ulawulo lwesikrini sokuchukumisa esikrelekrele, ukusebenza lula kunye nolawulo oluchanekileyo.

Ubunjineli beZityalo

-Uyilo lwezityalo

-Ukubeka iliso kwinkqubo, ulawulo kunye ne-automation

-Uphuhliso lweSoftware kunye nenkqubo yesicelo sexesha lokwenyani

-Ubunjineli

-Ukwenziwa koomatshini

Ulawulo lweprokjekthi

-Ucwangciso lweprojekthi

-Ulawulo lwendawo yokwakha

-Ukufakwa kunye novavanyo lwezixhobo kunye neenkqubo zokulawula

-Oomatshini kunye nokugunyaziswa kweplanti

-Uqeqesho lwabasebenzi

-Inkxaso kuyo yonke imveliso

Inkcazo yeProjekthi

-Ukuba nokwenzeka kunye nofundo lwengqiqo

-Iindleko kunye nokubalwa kweNzuzo

-Ubungakanani bexesha kunye nesicwangciso sobutyebi

-Isisombululo se-Turnkey, ukuphuculwa kwezityalo kunye nezisombululo zesimanje

Uyilo lweProjekthi

-Iinjineli ezinolwazi

-Ukusebenzisa itekhnoloji yamva nje

-Ukusebenzisa ulwazi olufunyenwe kumakhulu ezicelo kuwo onke amashishini

-Ukwandisa ubuchule obuvela kwiinjineli zethu ezinamava kunye namaqabane