Umzi-mveliso webhetri kunye nezinye izinto zokusetyenziswa kweMichiza eFluidized-bed Jet Mill

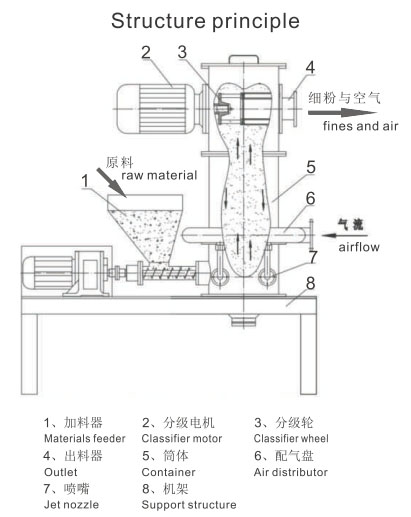

I-Fluidized bed pneumatic Mill sisixhobo esisetyenziselwa ukutyumza izinto ezomileyo zibe ngumgubo omkhulu, kunye nesakhiwo esisisiseko ngolu hlobo lulandelayo:

IMveliso yi-pulverizer yebhedi ene-fluidized kunye nomoya woxinzelelo njengesixhobo sokutyumza. Umzimba wokusila wahlulwe ube ngamacandelo ama-3, oko kukuthi indawo yokutyumza, indawo yothumelo kunye nendawo yokuhlela. Indawo yokuHlela ibonelelwa ngevili lohlelo, kwaye isantya sinokuhlengahlengiswa sisiguquli. Igumbi lokutyumza liqulunqwe ngumbhobho wokutyumza, i-feeder, njl.

Izinto eziphathekayo zingena kwigumbi lokutyumza nge-feeder material. Imilomo yoxinzelelo yomoya ingena kwigumbi lokutyumza ngesantya esiphezulu ngokusebenzisa imilomo etyumzayo exhotyiswe ngokukodwa. Izinto eziphathekayo zizuza ukukhawuleza kwi-jetting flow ye-ultrasonic kunye nokuchaphazela ngokuphindaphindiweyo kunye nokungqubana kwindawo ephakathi yokuguqula igumbi eliqhekezayo de lichithwe. Izinto ezityumkileyo zingena kwigumbi lokulinganisa kunye nokunyuka. Ngenxa yokuba amavili okulinganisa ajikeleza ngesantya esiphezulu, xa i-material inyuka, amasuntswana angaphantsi kwamandla e-centrifugal adalwe ukusuka kwii-rotors zokuhlelwa kunye ne-centripetal force eyenziwe kwi-viscosity ye-airflow. Xa amasuntswana angaphantsi kwamandla e-centrifugal amakhulu kune-centripetal force, amasuntswana arhabaxa anedayamitha enkulu kuneengqakumbana zohlelo olufunekayo aziyi kungena kwigumbi elingaphakathi levili lohlelo kwaye ziya kubuyela kwigumbi lokutyumza ukuze lityunyuzwe. Amasuntswana amahle ahambelana nobubanzi bamasuntswana omgangatho ofunekayo aya kungena kwivili lohlelo kwaye aqukuqelele kwisahluli sesitshingitshane segumbi elingaphakathi levili lokulinganisa kunye nokuhamba komoya kwaye aqokelelwe ngumqokeleli. Umoya ohluziweyo ukhululwa kwi-intaker yomoya emva konyango lwengxowa yokucoca.

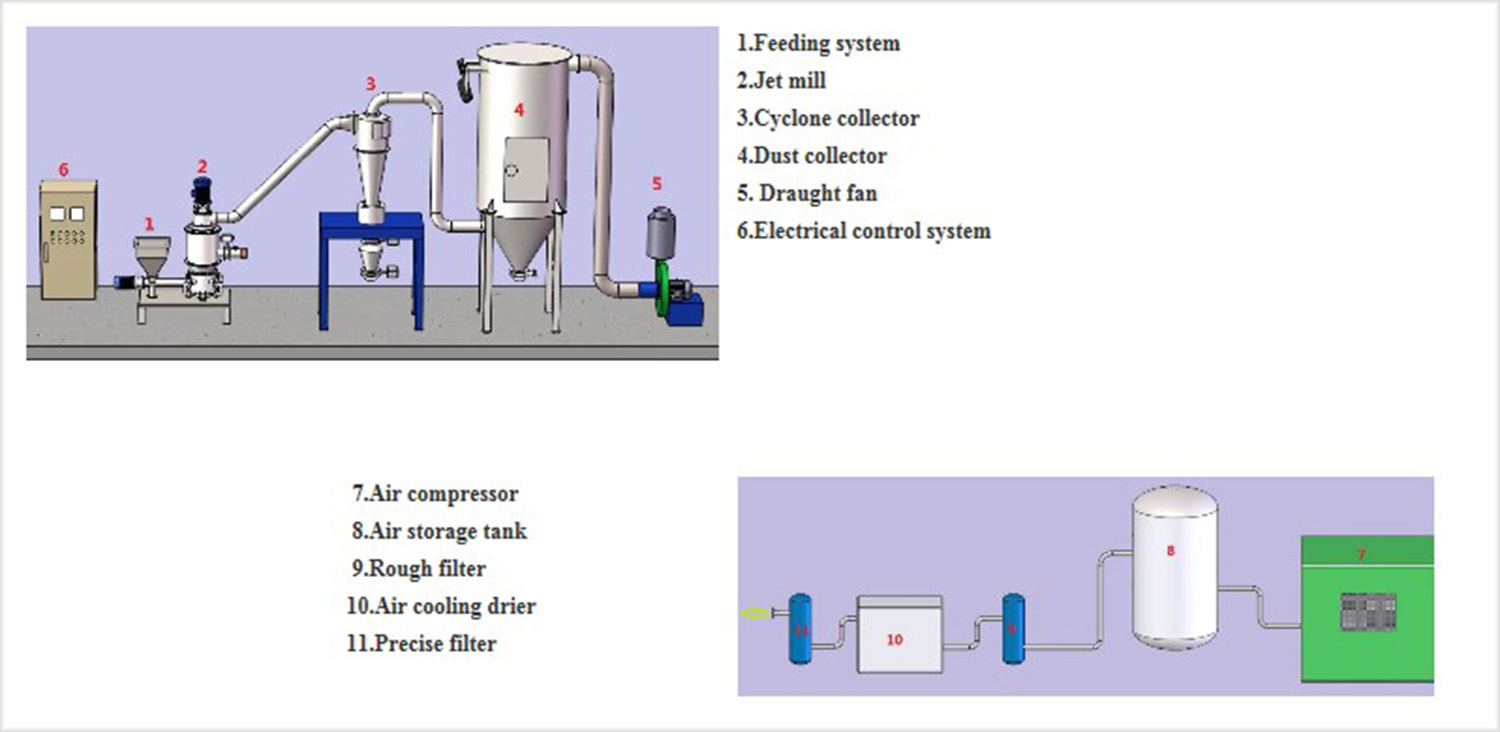

I-pneumatic pulverizer yenziwe ngecompressor yomoya, i-oyile remorer, itanki yegesi, isomisi esikhenkcezayo, isihluzi somoya, ibhedi yokucoca i-pneumatic, isahluli senkanyamba, umqokeleli, isithambiso somoya kunye nabanye.

Bonisa iinkcukacha

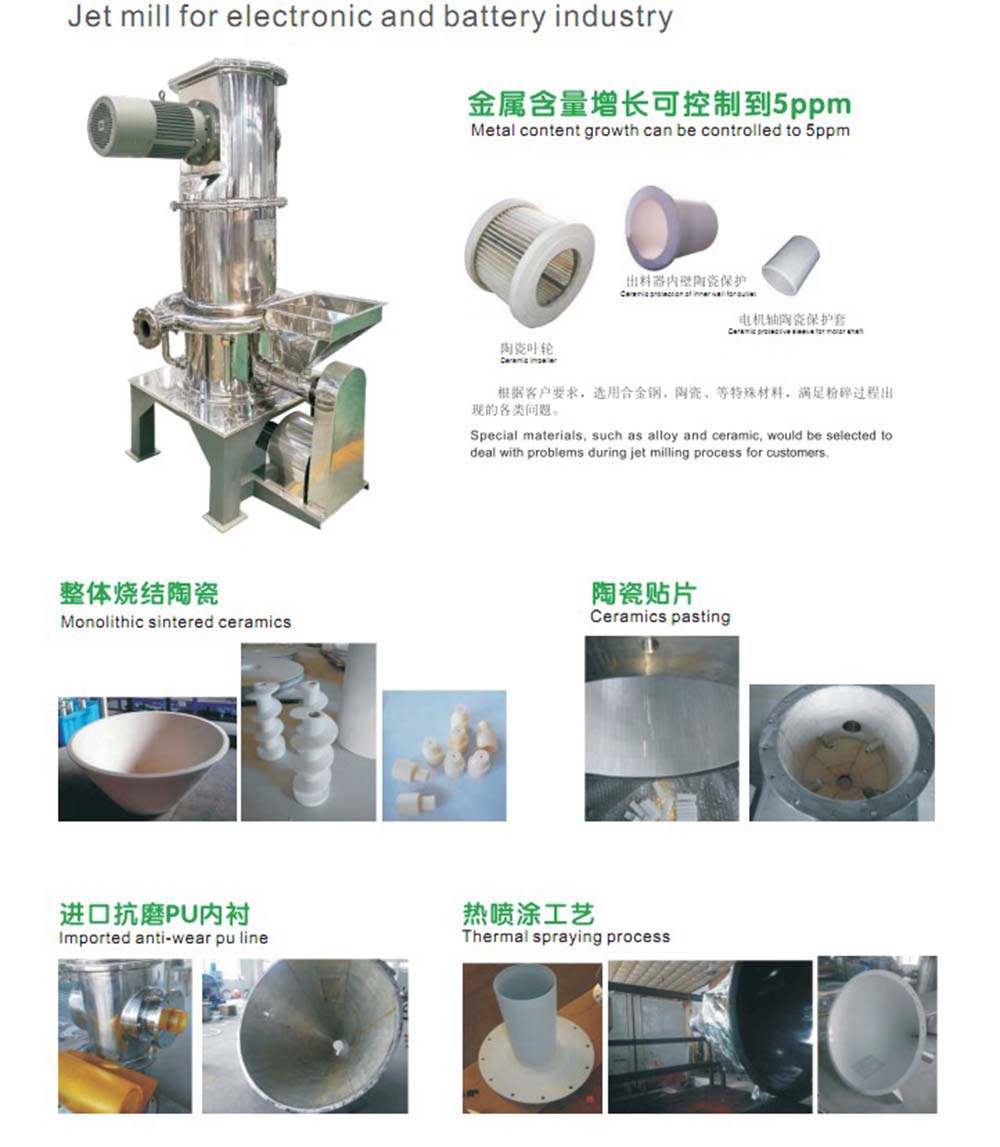

I-Ceramics yokuncamathisela kunye ne-PU lining kwiindawo zokusila ezidibanisa neemveliso ukunqanda isinyithi esilahliweyo esikhokelela kwisiphumo esingasebenziyo seemveliso ze-terminal.

I-1.Iingubo ze-ceramic ezichanekileyo, i-100% isusa ukungcola kwentsimbi ukusuka kwinkqubo yokuhlelwa kwezinto eziphathekayo ukuze kuqinisekiswe ukucoceka kweemveliso. Ngokukodwa ezifanelekileyo kwiimfuno zetsimbi zezinto zombane, ezifana ne-cobalt high acid, i-lithium manganese acid, i-lithium iron phosphate, i-Ternary Material, i-lithium carbonate kunye ne-Acid lithium nickel kunye ne-cobalt njl ibhetri ye-cathode.

2. Akukho ukunyuka kweqondo lokushisa: Iqondo lokushisa aliyi kunyuka njengoko izinto zixutywa phantsi kweemeko zokusebenza zokwandiswa kwe-pneumatic kunye neqondo lokushisa kwi-milling cavity ligcinwa liqhelekileyo.

3. Ukunyamezela: Kusetyenziswa kwizinto ezine-Mohs Ukuqina ngaphantsi kweBakala 9. ekubeni impembelelo yokusila ibandakanya kuphela impembelelo kunye nokungqubana phakathi kweenkozo kunokungqubana nodonga.

4.Amandla asebenzayo: Ukugcina i-30% -40% xa kuthelekiswa nezinye iipulverizer zomoya womoya.

Irhasi ye-5.I-inert ingasetyenziswa njengemidiya yokugaya izinto ezinokutsha neziqhumayo.

6. Yonke inkqubo ityunyuziwe, uthuli luphantsi, ingxolo iphantsi, inkqubo yokuvelisa ihlambulukile kwaye ikhuselwe kwendalo.

7. Inkqubo ithatha ulawulo oluhlakaniphile lwesikrini sokuchukumisa, ukusebenza lula kunye nokulawula okuchanekileyo.

8.Ubume obuqinileyo: igumbi lomatshini oyintloko liqulunqa isiphaluka sokuvala ukutyumza.

Itshati yokuqukuqela kukusetyenzwa okusemgangathweni kokugaya, kwaye inokulungiswa kubathengi.

| imodeli | QDF-120 | QDF-200 | QDF-300 | QDF-400 | QDF-600 | QDF-800 |

| Uxinzelelo lokusebenza (Mpa) | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 |

| Ukusetyenziswa komoya (m3/min) | 2 | 3 | 6 | 10 | 20 | 40 |

| Idayamitha yezinto ezondliwayo (i-mesh) | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 |

| Ukulunga kokutyumza(d97M) | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 |

| Umthamo (kg/h) | 0.5~15 | 10-120 | 50~260 | 80~450 | 200~600 | 400~1500 |

| Amandla afakiweyo (kw) | 20 | 40 | 57 | 88 | 176 | 349 |

| Izinto eziphathekayo | Uhlobo | I-diameter yeengqungquthela ezondliwe | I-diameter yamasuntswana akhutshiweyo | Isiphumo(kg/h) | Ukusetyenziswa komoya (m3/min) |

| I-Cerium oxide | QDF300 | 400(umnatha) | d97,4.69μm | 30 | 6 |

| Ukubuyiswa komlilo | QDF300 | 400(umnatha) | d97,8.04μm | 10 | 6 |

| Chromium | QDF300 | 150(umnatha) | d97,4.50μm | 25 | 6 |

| I-Phrophyllite | QDF300 | 150(umnatha) | d97,7.30μm | 80 | 6 |

| Umqolo | QDF300 | 300(umnatha) | d97,4.78μm | 25 | 6 |

| I-Talcum | QDF400 | 325(umnatha) | d97,10μm | 180 | 10 |

| I-Talcum | QDF600 | 325(umnatha) | d97,10μm | 500 | 20 |

| I-Talcum | QDF800 | 325(umnatha) | d97,10μm | 1200 | 40 |

| I-Talcum | QDF800 | 325(umnatha) | d97,4.8μm | 260 | 40 |

| Icalcium | QDF400 | 325(umnatha) | d50,2.50μm | 116 | 10 |

| Icalcium | QDF600 | 325(umnatha) | d50,2.50μm | 260 | 20 |

| Magnesium | QDF400 | 325(umnatha) | d50,2.04μm | 160 | 10 |

| Alumina | QDF400 | 150(umnatha) | d97,2.07μm | 30 | 10 |

| Amandla ePearl | QDF400 | 300(umnatha) | d97,6.10μm | 145 | 10 |

| Iquartz | QDF400 | 200(Mesh) | d50,3.19μm | 60 | 10 |

| Barite | QDF400 | 325(umnatha) | d50,1.45μm | 180 | 10 |

| Iarhente yogwebu | QDF400 | d50,11.52μm | d50,1.70μm | 61 | 10 |

| I-kaolin yomhlaba | QDF600 | 400(umnatha) | d50,2.02μm | 135 | 20 |

| Lithium | QDF400 | 200(Mesh) | d50,1.30μm | 60 | 10 |

| Kirara | QDF600 | 400(umnatha) | d50,3.34μm | 180 | 20 |

| PBDE | QDF400 | 325(umnatha) | d97,3.50μm | 150 | 10 |

| I-AGR | QDF400 | 500(umnatha) | d97,3.65μm | 250 | 10 |

| Igraphite | QDF600 | d50,3.87μm | d50,1.19μm | 700 | 20 |

| Igraphite | QDF600 | d50,3.87μm | d50,1.00μm | 390 | 20 |

| Igraphite | QDF600 | d50,3.87μm | d50,0.79μm | 290 | 20 |

| Igraphite | QDF600 | d50,3.87μm | d50,0.66μm | 90 | 20 |

| Iconcave-convex | QDF800 | 300(umnatha) | d97,10μm | 1000 | 40 |

| I-silicon emnyama | QDF800 | 60(umnatha) | 400(umnatha) | 1000 | 40 |